Matara-Beliatta rail track: Lankan engineers signal danger

View(s): 324

By Namini Wijedasa

The Chinese company extending the railway line from Matara to Beliatta is not qualified for the contract and follows practices and standards that seriously endanger the lives of those who will travel on that track, an influential engineers’ union has said.

The project is being carried out by China National Machinery Import and Export Corporation (CMC). It was an unsolicited proposal approved under the previous administration. The Central Engineering Consultancy Bureau (CECB) was appointed as project consultant.

Behind schedule: Sri Lankan engineers allege that substandard materials were being used to build the railway track. Pic P.de Silva

The contract was not only overpriced at Rs 40bn (US$ 278.2m), several instances have been identified of CMC using substandard materials and construction methods, the CECB Engineers’ Association (CECBEA) said at a news conference in Colombo. These were repeatedly brought to the notice of the authorities, including the Ministry of Transport.

CECB responded by removing the team head who supervised the project from its start; and replaced him with an engineer who, it is claimed, has little or no experience in railway or track works. The latter has also now handed in his resignation from the assignment.

The 400-member CECBEA called for Engineer M.M. Akram to be reinstated as team leader for the project. The Department of Railways has separately written to the CECB Chairman saying the replacement does not have the required know-how and that “the proposed change of Team Leader at this junction will hamper the quality output of the Project”. The CECB has not responded.

The union is speaking out because it fears there could be a disaster in future, its President Harshana Bulathsinhala said. The authorities, to whom complaints were made, removed Mr Akram from the project more than three weeks ago but are yet to take action on serious issues he raised regarding the company’s errant construction practices.

The choice of CMC for the Matara-Beliatta railway extension was questionable from the start, the union said. In 2012, the Exim Bank of China told the Sri Lankan Government that the company did not have the relevant experience to execute the project. The Bank insisted that the firm forms a joint venture with or subcontracts an engineering company.

CMC then tied up with China Railway No. 5 Group (CR5) but the CECB team repeatedly found serious shortcomings in their work. Mr. Akram made a presentation to substantiate his claims. He showed, for instance, how the company had tampered with a concrete beam (to be used in a bridge), even shearing off iron rods that were essential to guarantee the strength of the beam.

The CECB team detected instances where concrete was diluted beyond acceptable levels due to construction being done during heavy rains. As the contractor did not use suitable methods and machinery, certain works had to be performed over and again, leading to prolonged delays. When cracks appeared in the Wewurukannala Bridge, the contractor tried to cover them up with a cement mix. However, the CECB team forced the company to rectify the faults following due process.

The contractor on several occasions disregarded CECB instructions to maintain acceptable standards in the construction of stone walls. Engineers, once again, had to expend considerable energy to have the situation corrected. Many other defects were found.

The estimates given by CMC for both material and manpower were highly inflated, Mr Akram said. For instance, the company has priced one cubic metre of rubble masonry work at Rs 57,588 when the market price was only Rs 18,000; and one cubic foot of rubble masonry work at Rs 1,630 against a market price of Rs 509. The daily wage for a skilled worker is specified as Rs 3,960 when the market price is Rs 2,000; and for an unskilled worker as Rs 3,000 against a market price of Rs 1,500.

Chinese workers on several occasions threatened the CECB team, even prompting fears over their physical safety, the union said. And while the project is now in its final stages, there have been significant delays for which the Government should have claimed substantial compensation. Instead, the Transport Ministry extended the deadline for handing over the track, even against CECB recommendations.

Since August 2013, the contractor–who hails from a country with the world’s second longest railway network–has struggled to put in place the 27km track from Matara to Beliatta. A third deadline has now been given till December 2017, although the CECB insisted it should not go beyond September.

Since August 2013, the contractor–who hails from a country with the world’s second longest railway network–has struggled to put in place the 27km track from Matara to Beliatta. A third deadline has now been given till December 2017, although the CECB insisted it should not go beyond September.

Despite all this, the Transport Ministry is now set to award another US$ 15m (Rs 2.2bn) project to CMC to install signals at four stations on the extended line, yet another job the company has no experience to carry out. It might, once again, tie up with another venture–thereby pushing up costs to the Sri Lankan Government, owing to respective profit margins.

Tenders have not been called for the signalling contract. The basis for placing its cost at US$ 15m is not known. And an offer by the Railway Department’s own engineers to execute the project at Rs 250m has been ignored.

“This sort of thing also gives the Chinese Government a bad name,” said Sanjeewa Wijesinghe, CECB’s Deputy General Manager (Civil Works). One errant contractor must not be allowed to spoil the overall reputation of Chinese project activity in Sri Lanka. He said efforts were being made to convey this message to the Chinese Foreign Ministry through the Embassy in Colombo.

අදහස්(0)

අදහස්(0)  බැලූවෝ (2133)

බැලූවෝ (2133)

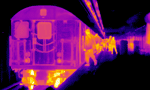

The Wildlife Conservation Department has decided to install Infra-Red cameras in trains travelling through forest areas known to be frequented by wild elephants. This new move is an attempt to save the wild elephants from being run over by trains.

The Wildlife Conservation Department has decided to install Infra-Red cameras in trains travelling through forest areas known to be frequented by wild elephants. This new move is an attempt to save the wild elephants from being run over by trains.